Bearings Purchasing Guide

Uncertain about the bearings to choose? This guide breaks down key terminology and facts about bearings, and highlights the best options for your specific riding or skating style.

1. Bearings Overview

Two bearings are necessary for a wheel to turn on its axle. They can significantly impact your riding or skating speed and experience.

It's important to keep all types of bearings away from sand, water, and moisture, as exposure under any circumstances can drastically reduce their longevity. Ensuring bearings are regularly cleaned and lubricated enhances their durability and performance. Click here to learn how to clean your bearings.

Using a spacer to bridge the gap between bearings is essential to prevent damage and ensure smooth rotation when the axles are tightened. Spacer size should match the axle size used.

8 mm spacer

6 mm spacer

Several factors influence bearing quality, including:

- Material

- Precision (ABEC)

- Lubrication

- Sealed or open (Removable Shield)

Which bearing type suits you best:

- If you're mainly riding/skating outdoors, we suggest sealed bearings with grease lubrication, as they resist dirt and dust effectively, requiring little to no maintenance.

- If you're primarily indoor riding/skating, open bearings that spin quickly and are simple to clean are suitable.

- For those interested in speed and long-distance runs, opt for high precision bearings lubricated with oil. They spin exceedingly fast and are easy to clean but are vulnerable to dirt.

2. Installation

You can usually press in a bearing using your thumbs. Correct installation aligns the bearing with the wheel hub. If protruding at any point, it’s incorrectly mounted and will be damaged while skating. Metal core wheels may present challenges in bearing installation; in such cases, use a rubber mallet or square wood piece to tap it in.

Never use a metal hammer, as it will damage both the bearing and void your warranty.

Alternatively, lubrication can assist in seating a bearing; remember, any excess lubrication must be cleaned up afterwards.

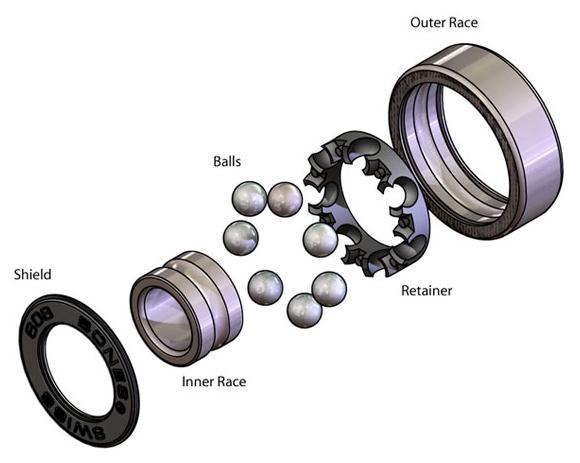

3. Detailed Look at Bearings

Material

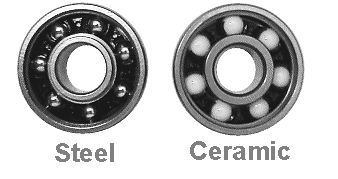

The material of bearings is crucial to their quality and longevity. While most bearings are made from steel, inexpensive varieties often comprise pressed sheet metal or hardened carbon steel and are not advisable for durability.

Higher-quality bearings are crafted from genuine bearing steel, such as chrome, titanium, or Swiss steel.

For ceramic bearings, typically used in speed skating, the balls are made of industrial ceramic (Silicon Nitride), boasting rust resistance and durability greater than steel.

There is a strong correlation between price and quality in bearings, with well-known brands generally offering reliable and durable products.

Precision/ABEC

Bearings classification adheres to the industry-recognised ABEC specification. ABEC ratings indicate how effectively bearings translate applied force. Higher ABEC grades offer greater precision, efficiency, and enhanced speed capabilities, though they do NOT automatically increase spin speed. ABEC ratings don't account for other critical factors, like spacer and wheel precision or material quality. Bearings do lose precision over time due to wear.

Please be aware that not all brands adopt the ABEC scale (e.g., Bones) and alternative bearing scales do exist.

ABEC stands for Annular Bearing Engineering Committee.

Lubrication

Bearings utilise oil or grease as lubrication. A bearing should never operate "dry" of lubrication, as this leads to melting, speed loss, or total blockage.

- Oil: Offers high speed due to less resistance. Thinner oils provide higher speed but need more frequent upkeep.

- Grease: Better resists water and dirt than oil. Requires minimal upkeep but increases resistance, thereby lowering speed.

Note: Water can remove all lubrication! If water dries and lubrication is absent, bearings may overheat, potentially melt, and make noise upon next use, necessitating replacement. However, if not used, they might be saved if thoroughly cleaned and oiled before the next run.

Shields/Seals

To block dirt, sand, and water access, a shield or seal is typically fitted on one or both sides of the bearing.

- A Shield is generally a metal barrier attached to the outer ring, with a minor gap to the inner ring (also termed as a dustproof bearing). Bearings with shields experience minimal friction, allowing easier rotation and greater speed. However, they are not fully protected against water and dirt.

- A Seal (pictured below) is crafted from steel-reinforced rubber, fitted to the outer ring, and gently contacts the inner ring. It delivers superior protection with virtually no maintenance but results in higher friction and slightly reduced speed.

4. Understanding Bearing Standards and Precision

Several elements contribute to ABEC grading, one being the eccentricity (roundness) of the inner ring track. Below is a table showing the maximum permitted eccentricity.

| Type | mm | Inches |

| ABEC 1 | 0.0075 mm | (0.000295") |

| ABEC 3 | 0.0050 mm | (0.000197") |

| ABEC 5 | 0.0035 mm | (0.000138") |

| ABEC 7 | 0.0025 mm | (0.000098") |

| ABEC 9 | 0.0012 mm | (0.000047") |

Higher ABEC ratings correlate with smaller part deviations in the bearing, meaning more energy is effectively transferred to the wheel.

ABEC and ILQ are not directly comparable, as ILQ is a brand, whereas ABEC is a standard.

ABEC ratings determine production precision but not strength or performance under load. Twincam, which produces ILQ, rates their bearing quality on a scale akin to ABEC, yet ILQ bearings feature 6 balls, contrary to the 7 in ABEC bearings.

To clarify, ILQ is not a recognised standard, unlike ABEC bearings, and should thus be regarded as an ungraded bearing from a professional inline bearing manufacturer, not optimal for industrial use.

Bones bearings are specifically engineered for skating and aren’t comparable with ABEC specifications.

The following outlines common bearing and shield terminology (bearing type is usually marked on the bearing along with its size, e.g., 608ZZ).

608

- Standard bearing

- 22 mm outer diameter

- 7 mm width

- 8 mm inside diameter

688

- Mini/Micro bearing

- 16 mm outer diameter

- 5 mm width

- 8 mm inside diameter

Z

- Shield, 1 metal shield

- Open on the other side for easy maintenance (keep the open side facing inside the wheel when installing)

ZZ

- Shield, 2 metal shields

- The shields are fastened with a small C-ring, which needs removal to take off the shield for maintenance.

2RS/RS/RZ

- Seal, 2 steel-armed rubber seals

- Seals fitted without C-rings, removable for maintenance using a needle with care.

BRS

- Seal, 2 steel-armed rubber seals (non-contact)

- Seals fitted without C-rings offering excellent water protection.