Guidance on Bearing Maintenance: Cleaning and Lubrication

To achieve optimal functionality from your bearings, it's highly recommended to regularly clean and lubricate them. This routine helps to extend the lifespan and sustain the endurance of your bearings, ensuring they operate at peak speed.

Advisory: Steer clear of water and sand at all times

Bearings subjected to damp or dirty environments will experience a significant reduction in operational longevity.

Steps for Maintaining Bearings on Skates, Skateboards, and Scooters

Step 1

You will need: A degreasing solution such as Fluid wash, a waterproof container, a push pin or box cutter, a small brush, and fresh oil/grease.

Begin by removing the bearings from the wheel. The YouTube video above demonstrates how to undertake this for skates, though the method is identical for both skateboards and scooters.

Detach the wheels to access and remove the bearings.

Step 2

Thoroughly clean the exterior of the bearings with a brush until they are entirely devoid of dirt.

Open bearings are straightforward to maintain, whereas closed bearings require careful shielding removal for maintenance.

Attend to cleaning the outer surface of the bearings.

Step 3

If your bearings are sealed, use a push pin to lift the seal.

For closed bearings with metal shields, a tiny C-clip may secure them. Remove this C-clip with the push pin before detaching the shield.

Also, clean the seals and C-clips if they are present.

Seals (without a C-clip) are carefully detached from the bearing using a push pin or box cutter.

Step 4

Submerge the bearings in a container filled with the cleaning solution, then agitate the container for several minutes. This action agitates and loosens any dirt accumulation.

Initially clean with a small brush, followed by applying the cleansing solution.

Step 5

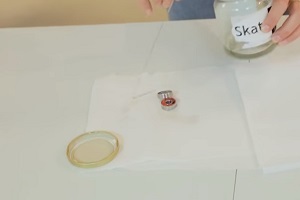

Once the bearings are out of the container, proceed to remove residual cleansing agent by spinning them. An air compressor can also effectively expel the fluid. Lay the clean bearings on a piece of cloth or kitchen tissue.

Bearings just extracted from the container with the cleaning solution.

Step 6

Evaluate the efficacy of the cleaning process. Hold the bearing by the inner ring and give it a gentle spin. A bearing that does not spin freely or emits a gritty sound requires additional cleaning. Repeat the cleaning with new cleaning solution if necessary, potentially needing 2-3 attempts for especially dirty bearings.

Test the cleanliness of the bearing by spinning it, as demonstrated.

Step 7

Position the bearings on a clean cloth or kitchen roll, ready for lubrication. Apply 1-2 drops of oil (excessive oil can attract dirt) or evenly distribute 3 mm of grease into the bearing.

Spin the bearings to ensure even distribution of the oil/grease, which can be efficiently done with a power drill.

Oil delicately applied in 1-2 drop increments onto the bearing.

Step 8

Finally, reattach the shields onto the bearings and reinstall them into the wheels of your skates, skateboard, or pro scooter.

Seals replaced onto the cleaned and lubricated bearings, which are then installed back onto the wheels.

Post Maintenance: Cleaning and Lubrication

Following the maintenance of the bearings, you may need to travel a short distance to ensure the oil/grease is adequately dispersed, allowing the bearings to reach their optimal performance.