Purchasing Scooter Wheels

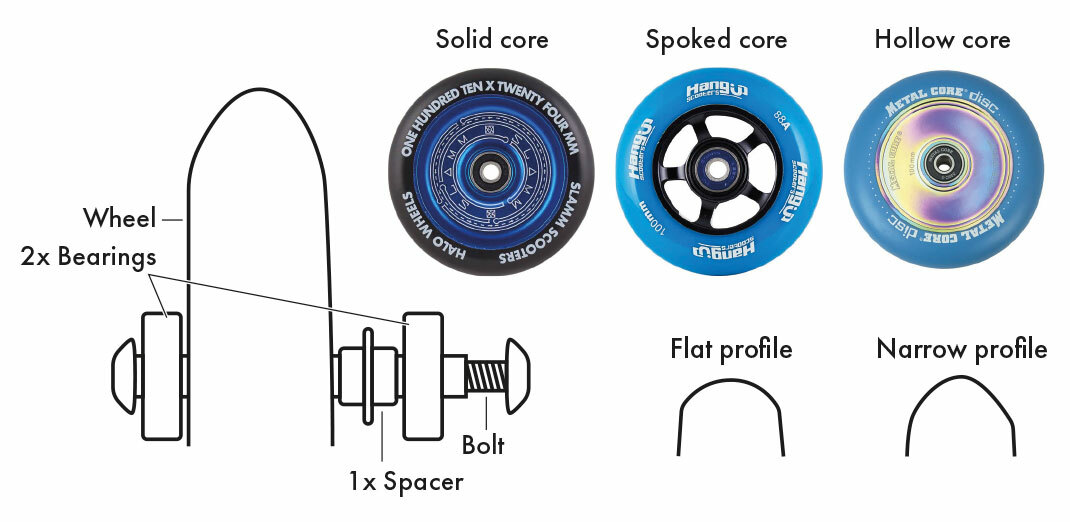

All wheels require 2x bearings and 1x spacer for proper operation.

The wheels vary in materials, dimensions, hardness, profiles, and core designs.

The diagram explains each component.

Cores

- Solid core. This robust core ensures maximum durability.

- Spoked core. Featuring holes and cutouts, this design creates a lightweight but also less robust wheel!

- Hollow core. An interior void offers reduced weight while retaining strength. (Not as strong as a solid core)

- Plastic core, Not illustrated. These tend to be less durable and slightly flexible.

- Honeycomb core, Not illustrated. Follows the hollow core principle, yet benefits from being even lighter due to perforated holes.

Profiles

- Flat profile (this design provides strength to the rubber and ensures maximum grip)

- Narrow profile (designed for speed)

Hardness

- The durometer scale ranges from 0-100a, with 100a being the hardest. Most scooter wheels are 85a.

- Harder wheels are more durable, slippery, and faster!

- Softer wheels wear quicker but offer excellent grip, ideal for parks and indoor settings.

- Manufacturers may not always specify wheel hardness, so testing is recommended.

Fitting Bearings into the Wheel

- Installing bearings in a wheel can be challenging; we've prepared a video guide for Fitting bearings into a scooter wheel with a metal core here.

Tips

- Always ensure bearings are aligned with the centre completely; misalignment can damage both the bearings and the wheel's centre.

- Using a hammer on the wheel or bearings during installation will void the warranty and your right to make a claim.

- Some wheels with a flat profile might not be compatible with forks that have a pointed profile.

- Replace worn wheels promptly for safety reasons and to avoid damaging the Flex fender brake!

Claim or Wear and Tear?

Wheels engineered for tricks are often subjected to high stress and, like all wheels, possess limited longevity.

Engaging in spinning tricks like a tail whip or a 360 repeatedly places lateral stress on the wheels. Frequent repetition in such cases can compromise the wheel material or cause pieces to break away.

So, how can you determine whether it qualifies as a claim or is damaged due to regular use?

Flat Spots

Braking aggressively and locking the brake can force the wheel against the tarmac, potentially causing “flat spots”. A flat spot appears as a straight line on the wheel bend and results in a bumpy ride.

A “flat spot” is not a manufacturing flaw and thus isn't warranted. The cause is improper scooter use; no wheels are harder than tarmac.

Dehub

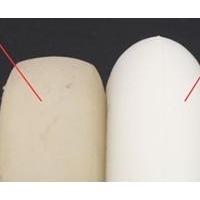

You will see below an image showing two wheels. On the left is a wheel with under 30% wear, still looking relatively new, alongside a completely new wheel on the right.

If a wheel appears quite new with less than 30% wear, and the urethane seems distinctly separated from the hub, it might indicate a manufacturing defect as pictured below:

However, if it shows over 40% wear and the urethane is detached or damaged but still connected to the hub, it typically does not signify a manufacturing issue.

If you suspect a manufacturing defect with your item, refer to our claim guide to learn what information you need to provide to initiate a claim.

Return to Assembling a Custom Trick Scooter

Return to Stunt Scooters Explained Here.